High Horsepower Capacity - Uniquely designed round-shape belt tooth enables the distribution of the load stress uniformly over the entire belt tooth. Since the belt tooth engages with the pulley groove without any interference, stress concentration at the root of the belt tooth can be eliminated. Innovation in tooth design and advanced synthetic materials give the Super Torque Drives exceptional strength and increased horsepower capacity.

Noise Reduction - The noise level will be relatively reduced because of almost perfect belt tooth compression effect in the pulley groove and smooth operation.

Longer Belt Life -Special groove profile prevents polygonal effect of the tensile member in engagement, resulting in less bending fatigue of the tensile member and longer belt life compared with trapezoidal timing belts.

Cost Reduction - Because of increased horsepower capacity, Super Torque timing belts can be widely used in high torque ranges previously serviced by chain and gear. Super Torque timing belts require no lubrication system nor retentioning maintenance, thus reducing initial and maintenance costs.

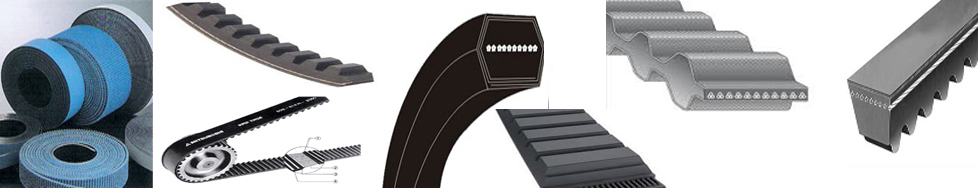

Construction

Nylon Facing - Wear-resistant nylon fabric with low friction coefficient assures smooth engagement of belt in mating pulley grooves.

Glassfiber Cord - Tough, heat-resistant glassfiber cords spirally wound are located within the belt pitch line, generating correct and positive belt engagement with pulley and negligible belt stretch in operation. In addition, special cords twisted in S & Z design prevent belt thrust force, resulting in longer service life.

Chloroprene Teeth - Correctly palced Chloroprene teeth engage with the pulley grooves and are inherently resistant to oil, heat and aging.

Chloroprene Backing - Flexible chloroprene backing protects the glassfiber cords from oil and moisture and also from frictional wear when power is transmitted from the back of the belt.

Belt Pitches - With Super Torque timing belt drives, as with gear or chain drives, circular pitch is a fundamental consideration. The pitch line of a Super Torque timing belt is located within the tensile member and is outside of the pulley outside diameter.

Belt Tooth Profile - Super Torque belt tooth is profiled with radius R, which has equal distance to the tooth width W on the pitch line and largeer tooth height than pulley groove depth - to make correct, positive engagement with the mating pulley grooves and noiseless operation.

| S4.5M TYPE SUPER TORQUE | |

| Size | Size |

| S4.5M 315 | S4.5M 396 |

| S4.5M 333 | S4.5M 504 |

| S4.5M 351 | S4.5M 801 |

| S4.5M 360 | S4.5M 905 |

| S4.5M 369 | S4.5M 950 |

| S4.5M 387 | |

| S5M TYPE SUPER TORQUE | |||||||

| Size | Size | Size | Size | Size | Size | Size | Size |

| S5M 255 | S5M 450 | S5M 560 | S5M 670 | S5M 750 | S5M 1000 | S5M 1165 | S5M 1530 |

| S5M 320 | S5M 475 | S5M 565 | S5M 675 | S5M 800 | S5M 1050 | S5M 1195 | S5M 1595 |

| S5M 350 | S5M 490 | S5M 575 | S5M 695 | S5M 830 | S5M 1115 | S5M 1225 | S5M 1800 |

| S5M 375 | S5M 500 | S5M 590 | S5M 700 | S5M 850 | S5M 1125 | S5M 1270 | S5M 2000 |

| S5M 390 | S5M 520 | S5M 600 | S5M 725 | S5M 900 | S5M 1135 | S5M 1295 | S5M 2525 |

| S5M 400 | S5M 525 | S5M 615 | S5M 730 | S5M 950 | S5M 1145 | S5M 1350 | |

| S5M 425 | S5M 550 | S5M 665 | S5M 740 | S5M 975 | S5M 1160 | S5M 1420 | |

| S8M TYPE SUPER TORQUE | |||||||||

| Size | Size | Size | Size | Size | Size | Size | Size | Size | Size |

| S8M 400 | S8M 584 | S8M 760 | S8M 920 | S8M 1040 | S8M 1248 | S8M 1360 | S8M 1624 | S8M 2032 | S8M 2800 |

| S8M 440 | S8M 600 | S8M 800 | S8M 944 | S8M 1056 | S8M 1256 | S8M 1400 | S8M 1728 | S8M 2240 | S8M 2848 |

| S8M 480 | S8M 632 | S8M 824 | S8M 960 | S8M 1120 | S8M 1280 | S8M 1440 | S8M 1760 | S8M 2272 | S8M 3200 |

| S8M 512 | S8M 656 | S8M 848 | S8M 976 | S8M 1160 | S8M 1304 | S8M 1480 | S8M 1776 | S8M 2400 | S8M 4400 |

| S8M 520 | S8M 712 | S8M 880 | S8M 1000 | S8M 1200 | S8M 1320 | S8M 1512 | S8M 1800 | S8M 2496 | |

| S8M 560 | S8M 720 | S8M 896 | S8M 1032 | S8M 1224 | S8M 1344 | S8M 1600 | S8M 2000 | S8M 2600 | |

| S14M TYPE | ||||

| Size | Size | Size | Size | Size |

| S14M 1190 | S14M 1750 | S14M 2240 | S14M 2660 | S14M 5012 |

| S14M 1246 | S14M 1778 | S14M 2310 | S14M 2800 | |

| S14M 1400 | S14M 1890 | S14M 2380 | S14M 3150 | |

| S14M 1540 | S14M 2002 | S14M 2450 | S14M 3500 | |

| S14M 1610 | S14M 2100 | S14M 2590 | S14M 3850 | |

For all intermediary sizes please contact our sales department.