- Total operator comfort

- Operator - friendly

- Easy maintenance

- Maximum manoeuvrability

|

|

| Total operator comfort Ergonomically designed tiller arm for stearing comfort and easy control | Rider comfort Vibration damped stand-on-platform which automatically returns to vertical position through spring |

For Video Please Click Here

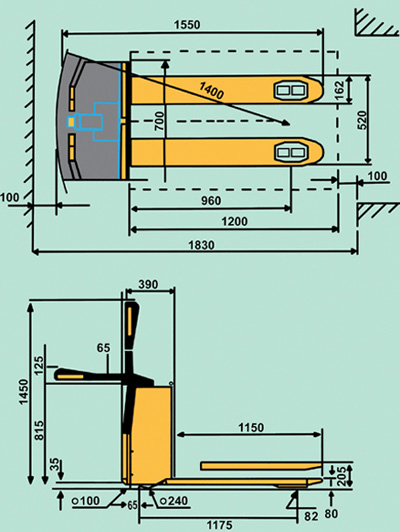

DPP 22/30 - These trucks are used for internal movement of goods.they are ideal for high intensity movement for long distances with compact design and small turning radius.They are ideal for manoeuvring in narrow aisles.

The DPP 22/30 are five wheeled pallet truck with a spring loaded centre positioned drive unit. The tiller arm steering designed for easy control & comfort offers operator a superb steering control at all speeds. All controls are conveniently positioned on the steering handle for easy accessing by finger tip control by the operator. The end of the control head terminates with the push contact for emergency reverse brake switch.The tiller arm and obstacles behind, for instance a rack. When the contact is pressed, the motor reverses direction and the vehicle will move away from the operator.

The 1.2Kw series wound drive motor is controlled by a Mosfet Electronic speed controller.This ensures smooth control of variations in speed and acceleration at all speed levels.

The drive unit, Hydraulics and Electronics are modular in design and can be easily accessed for service and maintenance.

The Battery is not lifted along with the forks, this feature saves around 20% of battery energy.

DRIVE UNIT

The fully closed oil lubricated gear box is integrated with 1.2Kw series wound motor. The drive unit design offers an excellent easy wheel shift.

SPEED CONTROLLER

The micro processor based mosfet speed controller enables fine tuning of all drive performance parameters with stepless controller.

INSTRUMENTAL PANEL

The panel contains emergency main switch, green and yellow indicator for status of battery charging.The feature includes a combination gauge with hour meter and battery indicator.

ELECTRONIC SYSTEM

2 x 12V, 150Ah batteries is mounted vertically for quick shift operations.

HYDRAULIC SYSTEMS

A 24V, 2Kw Electro-hydraulic pump (Japanese make) with 1.6 liter reservoir is provided.